Quality Assurance:

We supply the best Iranian chromite available, sourced from the finest suppliers in the country. Various analyzing milestones, including onsite analysis by reputable centers in Iran, Bandar-Abass analysis conducted by the world's leading testing company SGS, and destination analysis by CIQ, will be performed at different times to ensure order quality and quantity.

Price Assurance:

Iran Chromite group can supply an infinite amount of chromite at the lowest market price, thanks to their strong relationships with over 100 suppliers and miners. You don't have to believe us, compare our price with other suppliers and see for yourself. Don't hesitate to reach out to us today for a quote.

A legally robust contract.

Upon reaching a consensus on the commercial and technical aspects, a comprehensive contract will be issued along with a final invoice and a receipt confirming payment. These documents will serve as substantial evidence for any legal entities in Iran.

Get Sample First!

We offer a sample of 50 MT of any products you want for orders above 500 MT. Test the product first and ensure the quality and then place your order.

An Ultimate Guide to the Chromite Mine

Introduction: Chromite Mine

A chromite mine is a place where chromite, an iron, chromium, and oxygen oxide mineral, is extracted. These elements combine, resulting in a dark, glossy mineral which is the main source of chromium.

Chromium, in turn, plays a key role in various industries – from making stainless steel rust-resistant to giving that shiny finish to our beloved automobiles.

Now, onto the global stage. Chromite mining isn’t just about extracting a shiny mineral from the ground. It holds immense global importance. Think about it this way – every country wants to develop, right? And for development, they need infrastructure, skyscrapers, roads, vehicles, and more. The need for steel is paramount in all these sectors. And guess what steel needs to be strong and corrosion-resistant? Chromium! Chromite mining is essential because it feeds this global demand for chromium. Countries all over the globe are investing and trading in chromite products.

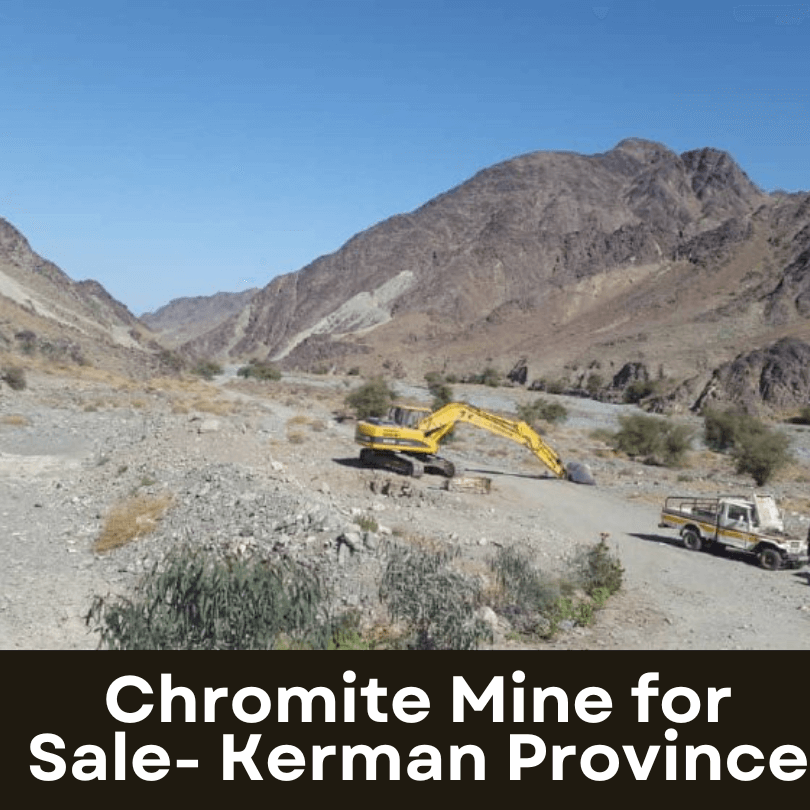

To obtain information about available chromite mines for sale or cooperation, contact IranChromite sales. Our database contains numerous exclusive mines, perfect for launching your chromite business in Iran.

Historical Background of Chromite Mining

The discovery of chromite

Chromite, composed mainly of iron, magnesium, chromium oxide and a bit of aluminum, was first discovered in the Ural Mountains of Russia in the late 18th century. It didn’t take too long before people realized its potential, especially for the manufacturing of the shiny, corrosion-resistant metal we all know and love – chromium.

How chromite mining evolved over time

I’ve seen the chromite mining landscape undergo some intriguing transformations over my career. Initially, methods were, let’s just say, pretty basic. Pickaxes and manpower – good old sweat and toil. But as time ticked by and technology progressed, we mining engineers started incorporating more advanced techniques, machinery, and processes. From open-pit mining to underground methods – the process has surely become more sophisticated.

Drilling, blasting, and hauling – the techniques have been refined considerably. By the mid-20th century, countries like South Africa, Kazakhstan, and India became major players in the global chromite export market. The shift was noticeable. It was no longer just about extraction – there was a focus on environmentally sustainable methods, efficient transport, and ensuring top-notch product quality for various industrial applications.

If you’re interested to buy chromite sand, check out the available offers at the link provided.

Understanding Chromite: The Basics

What is chromite?

Chromite is a brownish-black or deep green mineral that belongs to the spinel group of minerals. Its chemical formula is FeCr2O4. Chromite is the primary ore from which chromium is extracted.

When it comes to its significance, chromite is the sole ore of chromium, a metal used to induce hardness, toughness, and chemical resistance in steel. So, the next time you see stainless steel shining away, tip your hat to chromite.

The chemical composition and properties of chromite

Chromite has a chemical formula of FeCr₂O₄. Breaking it down, we’ve got iron (Fe), chromium (Cr), and oxygen (O) in the mix. What’s fascinating is its impressive spinel structure. This structure means that the iron and chromium ions are distributed evenly amongst the oxygen.

Now, for some of its properties – and this is where it gets kinda fun. Chromite boasts a high melting point. We’re talking about 1,900°C! It’s dense, hard, and has a shiny luster when fresh. Over time, though, it can develop a weathered, brownish-black appearance. It’s also resistant to weathering and doesn’t alter too easily. That makes it a precious find in the world of minerals.

The Mining Process

Generally speaking, surface mining is the most common technique, especially when the chromite deposits are found near the surface. Open-pit mining – where we dig a big pit and extract the ore – is quite popular. But sometimes, we’ve got to dig deep and use underground mining methods, especially when the ore deposits are located farther below the Earth’s surface. It’s a bit more complicated, and safety becomes even more crucial. Whew! Digging hundreds of feet below the surface? Not for the faint of heart.

Processing of Chromite Ore

Typically, this involves crushing the ore and separating the chromite from other minerals using gravity concentration, magnetic separation, or flotation methods. It’s a meticulous task – think of it like trying to find a needle in a haystack, but way messier. The outcome? We get what we call ferrochrome, an alloy of chromium and iron which is a high-demand product.

Rehabilitation After Mining

Once we’ve extracted all the chromite, we can’t just leave a gaping hole in the earth. That’s not how responsible mining works. Rehabilitation is crucial. We’ve got to ensure the land is returned, as much as possible, to its original state. This might mean refilling the pits, planting native species, and ensuring water quality is maintained. It’s our duty, really. The land gives us these valuable minerals; the least we can do is take care of it after we’re done.

Major Chromite Producers Globally

South Africa is the big kahuna in the global chromite scene. I mean, they’re producing a whopping majority of the world’s supply. Then you’ve got Kazakhstan and India nipping at their heels. These countries have vast reserves and continue to lead the pack in terms of chromite ore and concentrate exportation.

Speaking of major players, Zimbabwe and Turkey can’t be left out of this discussion. They’ve made significant strides over the past few years, and their contributions to the global market shouldn’t be taken lightly.

And, for a curveball—how about a mention of Iran? Yes, Iran! Major chromite mines in Iran are tucked away in areas like Faryab and Esfandagheh. If you ever find yourself on that side of the world, a visit to these mines would be like taking a step into chromite beating heart. They’re such a testament to the incredible progress Iran has made in the industry.

The Role of Chromite in Stainless Steel Production

How chromite contributes to the alloying process:

When we mine chromite, we’re extracting a mineral rich in chromium. And chromium? Well, it’s the unsung hero in stainless steel. When we mix chromium with iron during the alloying process, it creates a kind of protective layer on the steel. It’s this layer that makes the stainless steel, well… stainless! It’s an incredible chemical reaction where the chromium reacts with oxygen in the air to form a thin, protective and adhesive oxide film. This film is what stands between the steel and the world – it stops corrosion, discoloration, and rust. So, the next time you’re marveling at the shiny, non-corrosive properties of stainless steel appliances, just remember – chromite played a big role in that!

Why it’s an irreplaceable ingredient:

Chromite’s unique properties make it indispensable in stainless steel production. That protective layer I talked about earlier? Other minerals just can’t replicate it in the same way. Trust me, I’ve seen countless other compounds being tested, but nothing beats the efficacy of chromite. It’s this mineral that ensures your stainless steel remains durable and shiny. And in my ten years in this industry, exporting chromite products globally, I’ve seen its demand only go up. The mining world knows its worth, and so do I.

How to Benefit From a Chromite Mine

Buying a chromite mine to extract chromite lumpy

Now, when you’re thinking about buying a chromite mine to extract chromite lumpy, there’s a whirlwind of things to consider. The lumpy is a sizable chunk of chromite, and let me tell ya, extracting it is no small feat! But there’s an undeniable allure to it.

But buyer beware! A thorough evaluation of the mine is crucial. Look for clear, reliable, and documented evidence of the volume of chromite lumpy in the mine, get a qualified geologist to vouch for it, and always—always!—consider the ease of extraction. Because trust me, some mines, though rich, can be real tough nuts to crack.

Cooperation with the mine owner to produce refined chrome ore fines

And then, we’ve got the refined chrome ore fines. This, my friend, is where the rubber meets the road. Cooperating with the mine owner can open doors to producing this refined product. You see, while the lumpy is great, the fines are what many industries crave.

But the fines? They’re the crust that holds it all together. The fines are versatile and can be used in a variety of applications. So, the value they add can’t be overstated. But, here’s the catch – refining requires technique and investment. So, when you cooperate with the mine owner, you’re not just pooling resources. You’re blending expertise. Think about it – two minds, two sets of hands, working together to create something incredibly valuable. It’s synergy in action!

But remember, it’s essential to have a clear agreement in place—legalities, profit sharing, and all that jazz.

Conclusion:Chromite Mine

There are numerous chromite mines around the world to obtain chromite from. The provinces of Kerman and Khorasan in Iran have numerous large mines with abundant deposits of chromite ores.

Exporting chromite isn’t just about packing it up and sending it off, no sir! It’s about ensuring the quality, meeting international standards, and making sure everything is environmentally sustainable. It’s not just a business; it’s a responsibility.

Frequently Asked Questions

What is the largest chromite mine in the world?

The largest chromite mine in the world is the Bushveld Igneous Complex in South Africa. This massive geological formation contains a significant portion of the world’s known chromite reserves.

What industries rely most heavily on chromite?

Stainless Steel Production,Refractory Industries,Chemical Industry,Foundry Sand,Plating and Catalysts are the industries that rely most heavily on chromite.

How to monitor the price of chromite?

Chromite prices can be monitored through various commodity price reporting agencies like www.ferro-alloys.com, trade publications, or industry associations that track and report on the market dynamics of the metal and its ore.